Lean for Small Businesses

Lean for Small Business - Benefits

The following are the key benefits of adopting lean for small business.

ü Lean for small business is customer centric and facilitates acquiring and retaining the customers.

ü Reduces cost and improves productivity

ü Enhances your reputation for error free, timely delivery of product/ service and reliability to your customer is the key outcome

Expert Quotes

“All we are doing is looking at the time line, from the moment the customer gives us an order to the point when we collect the cash. And we are reducing the time line by reducing the non-value adding wastes.” Taiichi Ohno

“Continuous improvement is not about the things you do well — that’s work. Continuous improvement is about removing the things that get in the way of your work. The headaches, the things that slow you down, that’s what continuous improvement is all about.”–Bruce Hamilton

Why Lean for small Business

Lean is a systematic approach to eliminate waste in all the areas of a business. Lean can also be defined as an activity for which customer will not pay. Lean small business thinking adds value to your customer and reduces cost. This approach should be adopted by the small business owner right from the beginning especially if the business is operating in B-B space.

Why it is easy to adopt?

Lean is always driven by visionary top management in large corporations. However in small businesses the decision making and implementing is much easier as the owner is the driver of this initiative.

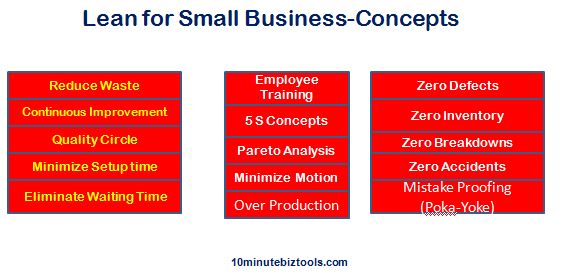

Lean For small Business-The Concepts

How Jay the CEO implemented?

The real life story of Jay who along with his eight friends was running an auto component manufacturing decided to implement lean concept right from the start of the business.

Picture modified from source-free diigitalphotos.net

Customer Retention Strategy

Jay’s business is running for two decades and not a single customer has left him. He is the first preferred vendor as customer is the key focus of his lean arrangement strategy.

Small Group Activities (Quality Circle)

Customer centric quality challenges were addressed proactively. Small group activity, Waste reduction and 5 S concepts were adopted very early.

Partnership with Customers- a win-win approach

The Customers technology departments helped in solving technical problems. The cost savings were split two ways.

5S Concepts

The specifications for the same type of rubber component for each of the five customers were marginally different. The shop floor was running all these simultaneously (45 SKU’s) in addition to manufacturing their own branded products. Jay’s customers will expect no mix up in the finished product when they receive at their warehouses. The technical and production personnel devised color codes to avoid mix up. The mixes up were rare and not even three to four instances over a period of five years. This is a solid proof that 5S concepts were implemented.

Kaizen (Continuous Improvements)

ü The company developed its own moulds for the rubber component as the mould requirement is substantial. They could produce moulds at a 60% cost of outside vendors.

ü The output from curing presses is critical and was able to reduce cure cycles to improve productivity from curing presses. They became benchmark to many other manufacturers.

ü The fuel price accounts for 20% of cost of production. They could use shredded and bundled currency notes in the boiler at half the cost of the conventional fuel. Further they designed the boiler to use multiple fuels and even rice husk was used.

ü Developed a unique strainer to remove foreign matter from rubber compound and consequently reducing rejection rate in finished rubber components .Achieving yet another bench mark among industry in waste.